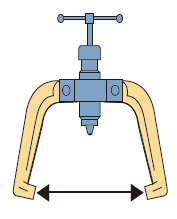

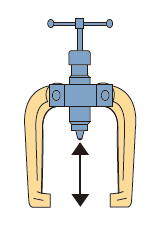

Bearing Puller guide: choose right puller for your work

DNT pullers are manufactured to a very high specification and subjected to rigorous testing - far exceeding their stated capacities. The legs and beams are drop forged from high quality steel and then heat treated for extra strength and durability. Pullers are normally classified as either hydraulic or mechanical with many different types within these two styles

Choosing the right puller for the job

|

|

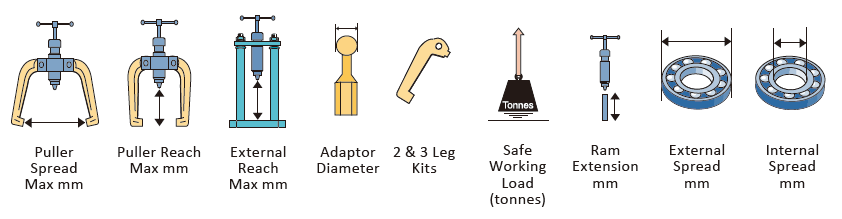

Decide what ‘spread’ is

required. This is

determined by the width of

the part to be pulled. |

|

Estimate out what ‘force’ is required.

More force may be required for rusted

parts or where there is a large area of

surface contact. Hydraulic pullers

enable maximum force to be applied

with minimum effort. Alternatively,

choose a puller whose force screw

diameter is at least half the size of the

shaft of the item to be removed. If in

doubt, use the next largest - using an

undersized puller will slow down the job

and lead to frustration

|

|

Always use a 3 leg puller if possible. This gives a better load distribution and is much safer in use. |

|

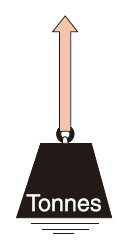

Decide what ‘reach’ is

required. This must be at

least equal to or larger than

the depth of the part which

needs removal. |

||

Types of Puller

|

These have a simple, grease-filled ram instead of a mechanical force screw, producing extra power with ease. The spring loaded plunger provides direct, non twisting application of thrust which is more effective and more secure. |

|

Blind Housing Bearing Removers

These operate without the need to

dismantle machinery or remove the

running shaft. |

|

Loadstar Hydraulic Pullers

Various styles available; Loadstar

8, 12 & 20 Tonne and Loadstar ‘Plus’

20, 30 & 50 Tonne. For heavy duty

pulling and extracting. |

|

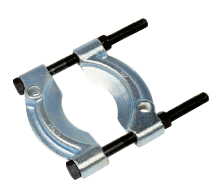

Separators

For where all round support is required

or where there is insufficient space for

standard puller legs |

|

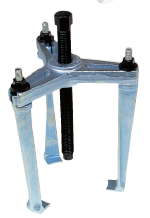

Mechanical Pullers

These use a mechanical force screw |

|

Slide Hammers

Used when there is no shaft, making

a conventional puller unsuitable. |

|

Thin Jaw Pullers

These have special legs for use where

clearance is limited behind the gear or

bearing race.

Available in both hydraulic and

mechanical. |

|

Split Collet Extractors

For blind housing internal use. The split

collet is pushed into the centre of the

bearing and then expanded via the hex

nut on the end of the collet. |

Quick Reference Guide