What are bearing pulllers

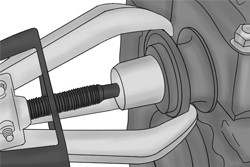

Bearing pullers are used to remove parts such as bearings, gears or pulleys from a shaft.

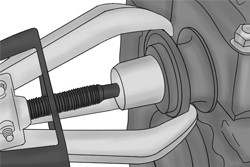

They have legs which circle around the back or inside of a part, and a forcing screw which centres up against the end of the shaft. As the forcing screw is tightened, the arms pull the part towards the end of the shaft.

A bearing puller is used to remove bearings, gears or pulleys, which are components that are in almost constant use. Because of this, they become worn or even damaged and need to be replaced.

The puller’s specially-designed claw legs fit comfortably around or inside these components and a forcing screw applies force to make removal simple, with minimal effort for the user.

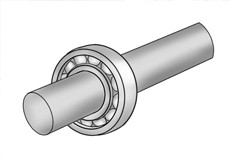

Bearings

A bearing is a part of a machine (such as an engine) that compels relative motion. Put simply, this means that a bearing rotates at the same speed as the rotating component; this helps to reduce friction between the moving parts.

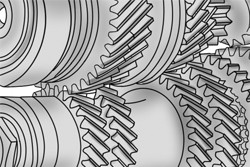

Gears

A gear is a wheel containing teeth that work with others to alter the relation between the speed of a driving mechanism (such as the engine of a vehicle) and the speed of the driven parts (the wheels).

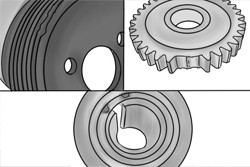

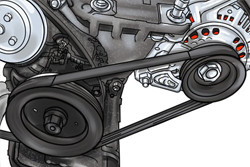

Pulleys

A pulley is a grooved wheel attached to a crankshaft. The pulley is connected by a belt that directs power to all the systems in an engine.

This is a two legged bearing puller removing a pulley from a shaft.