How do hydraulic nut splitters work?DNT Tools

How do hydraulic nut splitters work?

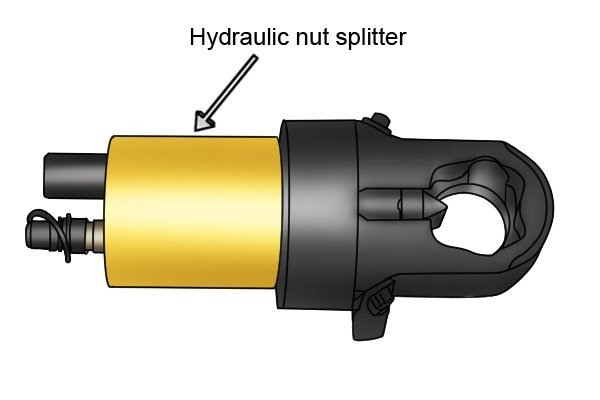

A hydraulic nut splitter works in the same way to split the nut, but instead of a screw forcing the chisel into the nut this action is performed by a hydraulic ram driven by a separate hydraulic compressor.

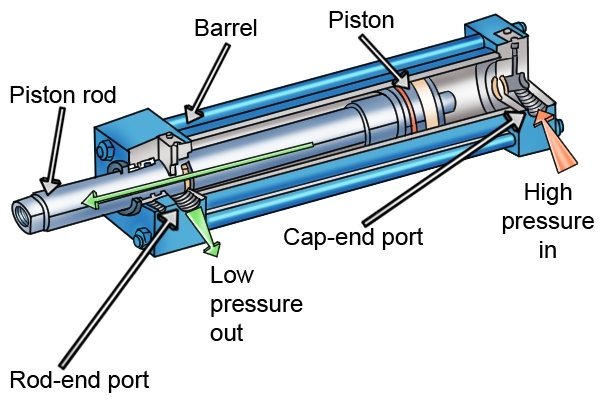

Hydraulic fluid is pumped into the piston barrel at the cap end port, creating a high pressure area behind the piston, while hydraulic fluid is pumped out of the piston barrel at the rod end port, creating a low pressure area in front of the piston.

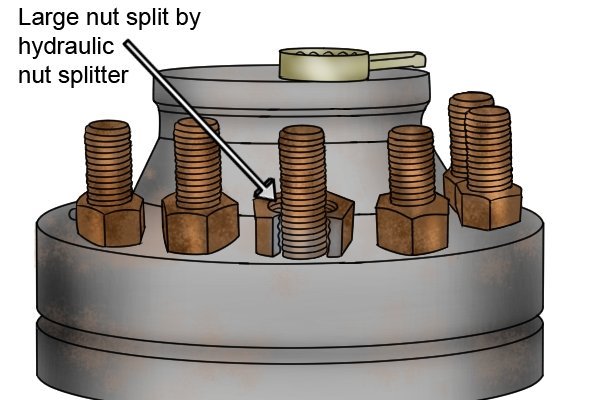

This pressure difference either side of the piston moves the piston forward in the barrel, which pushes the piston rod forward, which in turn pushes the chisel of the hydraulic nut splitter into the nut. Huge forces can be achieved with hydraulics, which is why they are used on large industrial nut splitters for splitting large nuts.