How to Remove a Stubborn Nut/Bolt -DNT Tools

Our last step if the nut splitter doesn’t work (or appeal to your stubborn bolt scenario) is use an angle grinder to cut the head off the bolt. Simply grind the nut and bolt until the nut no longer exists and pull the bolt right out.

This works great just be very careful as angle grinders can be a dangerous tool, they spin exceptionally fast (8000+ RPM) and have no anti kick mechanism. If your are not careful, the grinding disc may shatter and fly apart in all directions. The grinding also produces a lot of heat and sparks. BE CAREFUL!

Oops! You just broke off the head of the bolt you were trying to extract, leaving you with a stuck bolt and no way to remove it. Luckily there's one last way before drilling and retapping.

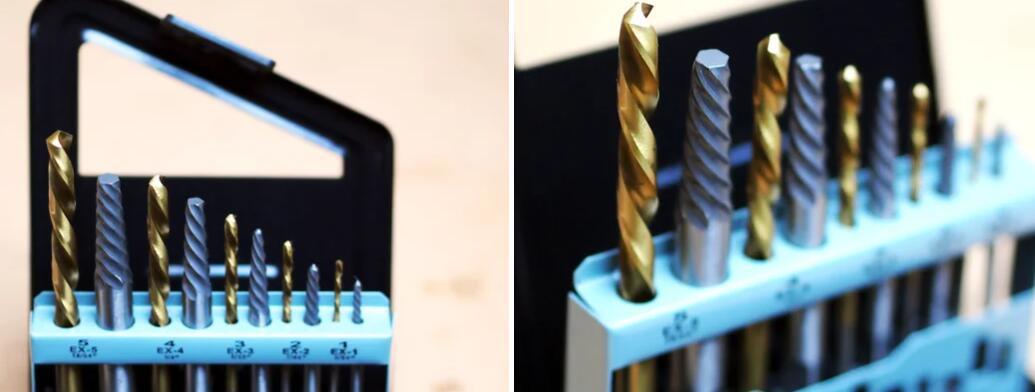

Go to an auto parts store and look for a Bolt Extractor, it’s a nifty tool that screws in the same direction as the bolt unscrews and allows you to drill into stuck bolt and keep turning it tighter and tighter until the bolt comes free and out. My bolt extractor kit came with a reverse-threaded drill bit, allowing you to drill into the bolt and then back the bolt out using the bolt extractor. It's a GREAT TOOL and will save a lot of headaches

This a relatively new method I have learned from a friend of mine! I wanted to add this to the list. A great way to remove a stubborn bolt is to "shock" it loose. When I say shock it loose, I mean hammer it! To be more precise, an Air Hammer. Using an air hammer on low pressure will make a nice vibrating but strong tool enough to loosen rust sometimes. Believe me, It works. If you tune the air pressure correctly, It will have a distinct hum. On the other end of this spectrum, if the first doesnt work, is to use a blunt or pointed tip on the head of a bolt with full PSI to the tool. This rapidly hammers it breaking the rust up mechanically. Even greater when penetrating oil has been applied. I have found this works very, very well. To my recent discovery, There is actually a brake bleeder tool made by Phoenix Systems called a Bleeder Buster. It works on the basis of a hammer action while putting rotational force on the stubborn bolt! I got a set from them, and I can confirm that it works very well!

Another option for removing a rusty and stripped bolt? You can always repair the hex portion of the faster! How? Its simple! A great way to do this is to add a new nut to the old bolt head! A great way to do this, is to use a wire brush to clean the head of the bolt. Pretty clean is acceptable. From here, An appropriate sized nut can be MIG/Wire Feed welded on top of the bolt to provide a new gripping surface for the wrench onto the bolt! Nifty eh? Well, Guess what! This heating to cherry read while welding is also a great heat shock to the corrosion holding the fastener on! This makes it easier to remove!

One last tool I use often in my own work, Which is a life saver if you have it, Is an impact gun! Be it battery, corded, or an air impact tool! Heck, Even manual impacts work! These tools focus on a power and fast rotational hammering action to shock and loosen the bolt in one motion! They are much less likely to round off a bolt then using a breaker bar! However, They tend to occasionally snap rusty bolts off unfortunately. Use with care, Especially if you have a powerful one! There is not much to them, Simply put them on a rusty nut and depress the trigger and let the tool hammer away!