Are there any alternatives to a nut splitter,how many ways to extractor rust nuts?

time2022/06/17

- Are there any alternatives to a nut splitter,how many ways to extractor rust nuts-Reliable manufacturing vendor on workshop tools

Are there any alternatives to a nut splitter,how many ways to extractor rust nuts?

There are several tools and techniques for trying to remove a rusted or damaged nut. In most cases these methods will be tried before using a nut splitter – once these other techniques and tools have failed a nut splitter may be the only option left.

No.1 Penetrating oil

This is often the first thing to be tried on a nut that’s corroded onto a bolt or stud. Spray this onto the nut and it penetrates the corrosion, dirt and grime that is seizing the nut onto the bolt. Penetrating oils also contain lubricants that that reduce the friction between the nut and the bolt’s threads, making it easier to turn the nut.

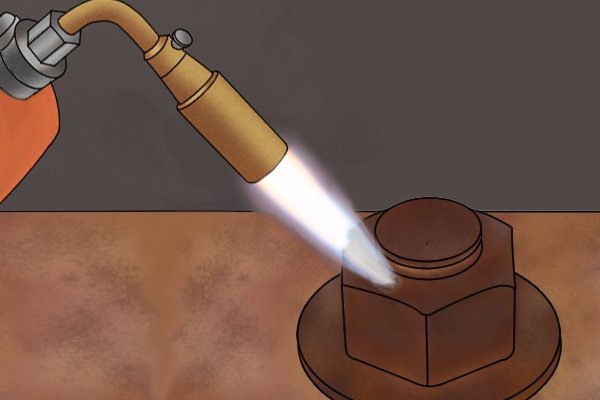

No.2 Heating the nut

This technique involves using a blow torch or oxy-acetylene torch to heat one side of the nut, it is often used in automotive workshops. As it is heated the nut expands and so breaks the rust that is holding it tight on the bolt.

Once the nut has been heated, remove the torch and apply paraffin wax to the cooler side of the nut. This will cause the wax to melt and be drawn by a capillary action into the threads of the nut and bolt, where it acts as a lubricant. Leave the nut to cool and then try removing it again. This technique can obviously only be used in certain circumstances.

No.3 Freezing the bolt

This method works on the same principle as heating the nut, but instead causes the bolt to contract, thus breaking the rust that is holding on the nut. Freeze sprays are simply sprayed onto the bolt and as they contain penetration oil as well as a freezing agent, once the rust bond with the nut is broken the penetrating oil can work into the bolt’s threads, making it easier to remove the nut.

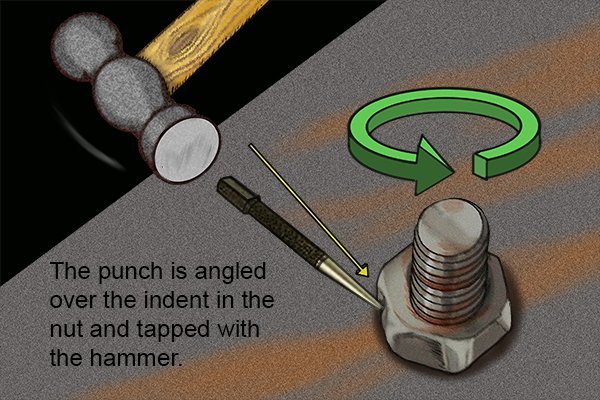

No.4 Tapping the nut with a punch

This is the technique often used on a damaged or rounded nut that can no longer be turned with a socket or spanner. First a small indent is created on the nut’s flat by tapping the punch with a small hammer at a right angle to the nut, into the centre of one of its flats.

The punch is then angled over in the indent you have created, so that as it is struck with the hammer it forces the nut to turn slightly in an anti-clockwise direction. The process of creating an indent and forcing the nut to turn slightly may to be repeated several times before the nut can be removed.

This technique not only damages the nut so it can not be reused, it requires plenty of access around the nut for you to use the punch and swing a hammer, as well as taking a lot of time. Because of this, if you have a nut splitter available you will often be able to remove the nut with it in less time and with less risk of damaging the item the nut is attached to.