pulley puller instruction-DNT-DN-A1094

time2022/10/21

- pulley puller instruction-sourcing tool factory from China-original tool manufacturer-Chinese-OEM-Custom

Pulley Puller instructions

Name | Pulley Puller |

Item No | DN-A1094 |

|

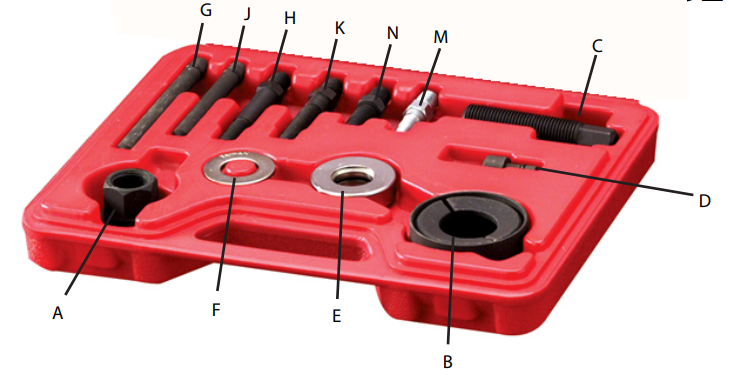

Parts No

|

PART DESCRIPTION |

A | PULLER BODY |

B | JAW & SLEEVE ASSY (3 PCS) |

|

C

|

JACK SCREW |

D | BUTTON |

|

E

|

BEARING |

|

F

|

THRUST WASHER |

G | PULLER PIN FOR QUAD 4 |

H | SCREW INSTALLER FOR QUAD 4 |

J | PULLER PIN FOR GM 3.1 |

K | SCREW INSTALLER FOR GM 3.1 |

M | SCREW INSTALLER FOR FORD 4.6 MODULAR M8x1.25 |

N | SCREW INSTALLER FOR ALL OTHERS |

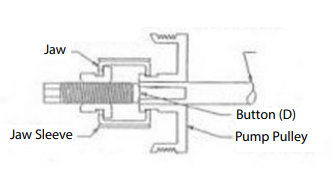

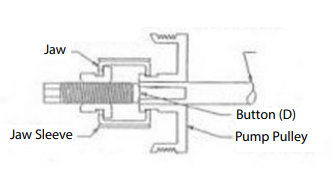

A: General Use Instructions For Removal

1. Coat jackscrew (C) with lubricant and thread into puller body (A)

2. Push button (D) into hole in jackscrew (C)

3. Assemble jaws (B) over puller body (A) and pulley flange

4. Hand tighten jackscrew (C) and slide jaw sleve into position over jaws

5. Hold puller body (A) with 1” wrench. Turn jackscrew (C) with 1/2”

wrench until pulley is removed

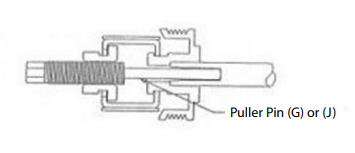

B: GM 3.1 & Quad 4 Instructions For Removal

1. Coat jackscrew (C) with lubricant and thread into puller body (A)

2. Push appropriate puller pin (G) or (J) into hole in jackscrew (C)

3. Assemble jaws (B) over puller body (A) and pulley flange

4. Hand tighten jackscrew (C) and slide jaw sleve into position over jaws

5. Hold puller body (A) with 1” wrench. Turn jackscrew (C) with 1/2”

wrench until pulley is removed

C: Pulley Installation (All Models)

1. Coat jackscrew (C) with lubricant and thread into puller body (A)

2. Insert small end of appropriate screw installer into jackscrew (C) and tighten

3. Place bearing (E) over jackscrew (C) next to puller body (A) followed by thrust washer (F). This sequence will help protect the bearing

4. Insert pilot end of appropriate screw installer through pulley and thread into pump shaft until screw installer bottoms

5. Hold jackscrew (C) with 1/2” wrench and turn puller body (A) with a 1” wrench until pulley is in position